Custom glass & Door fittings dimensions & Maintenance;

Customized glass;

Stall windows with custom-made glass, specifically for this window, are cut by our glass supplier and cannot be returned, because we cannot return to our glass company with pieces of glass, that is really not possible!!

Door fittings dimensions & maintenance;

Before making a purchase that is important with regard to dimensions, it is very important that you measure everything correctly in order to avoid returns that have to do with dimensions, after all, you are responsible for the costs of returning the package, which is just a waste.

Below is a basic explanation of door fittings;

What type of mortise lock do I have?

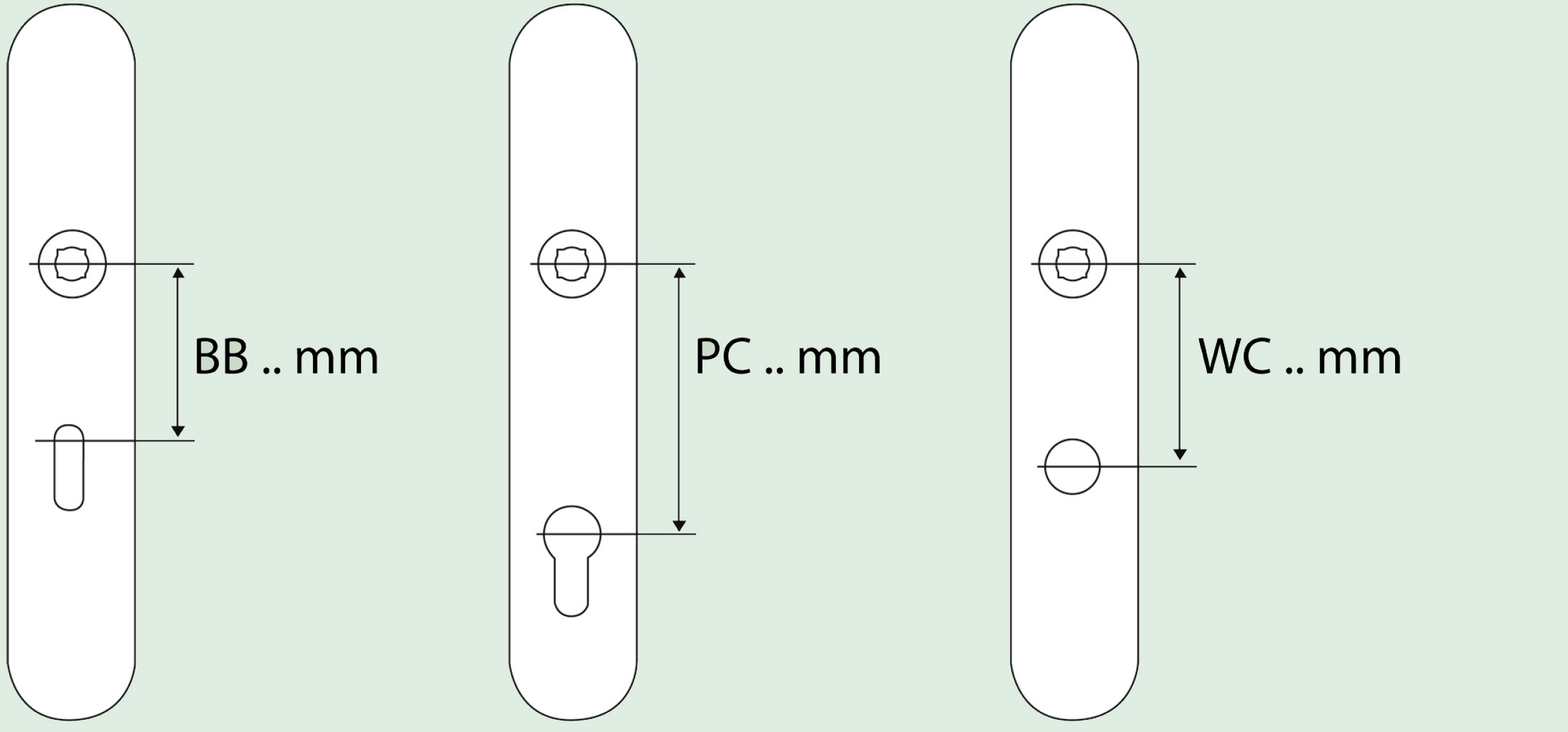

To determine which shield applies to your situation, you must first look at the type of lock it contains. Nowadays this is in many cases a profile cylinder (PC), but it is also possible that you lock your door with a fur beard key (BB). The third option is the toilet lock that you operate with a rotary knob (WC).

What is the center-to-center size of my mortise lock?

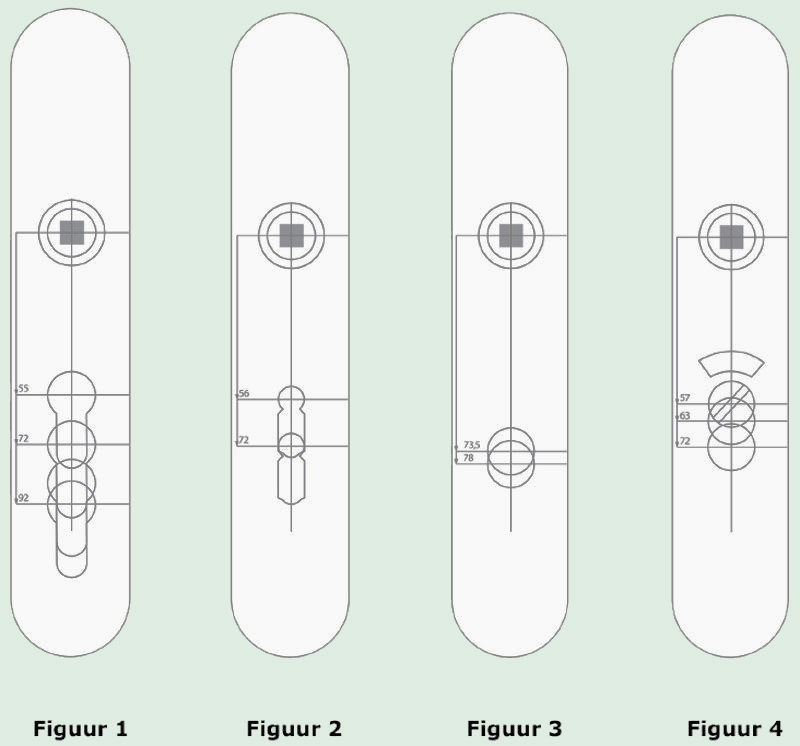

To arrive at the correct dimensions, calculate the center-to-center size of your mortise lock - also known as the lock opening. This is the distance between the center of the crank hole (the part where the handle falls into) and the center of the keyhole. The image below shows the exact location of the center of the keyhole for each type. Most common are 55, 72, 92 mm

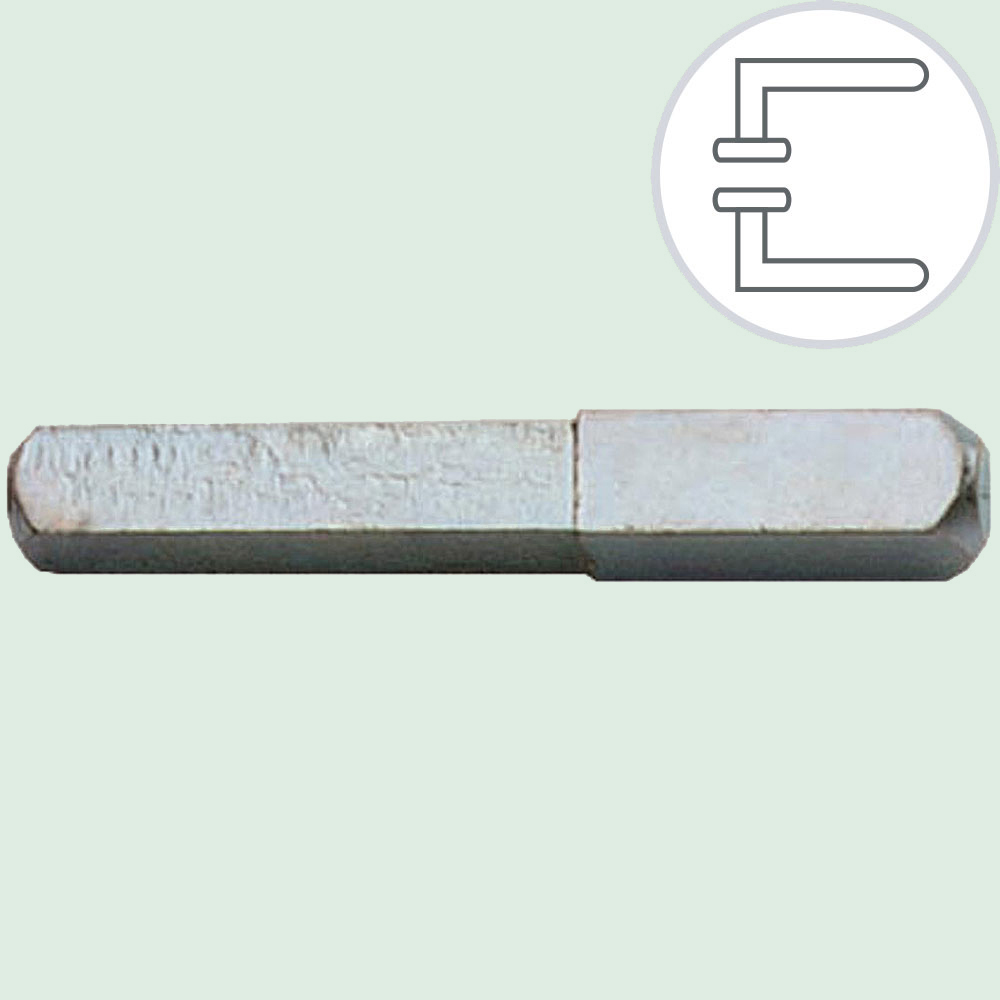

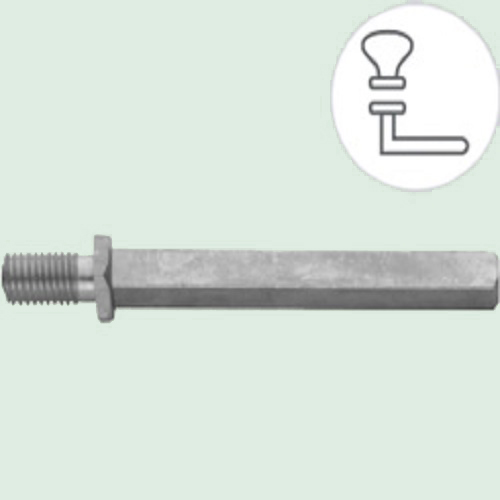

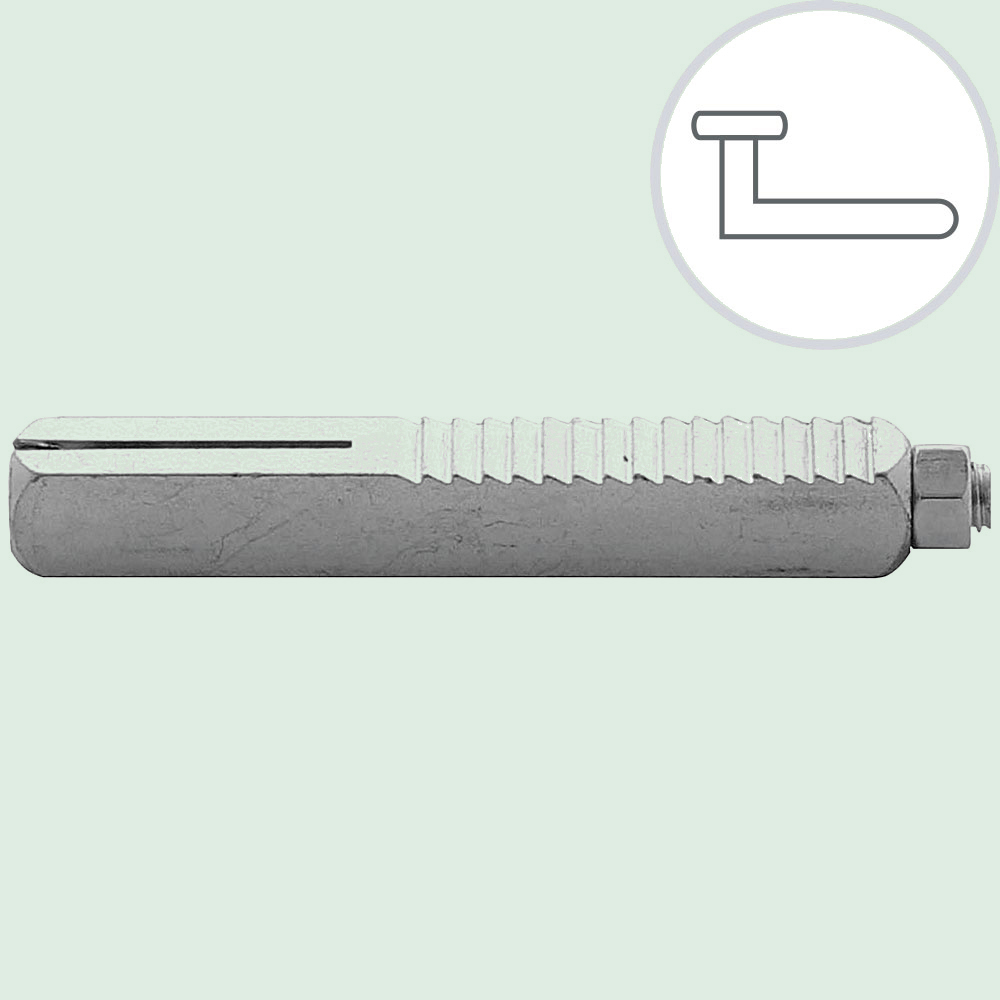

Crutch pins;

Handle pin, for attaching the door handles, are usually 8x8mm or 10x10mm, 8x8mm can be thickened to 10x10mm with an adapter sleeve and the length is determined by the thickness of the door, 130mm length is normal for a door of 75mm thick.

Different types of spindles;

Double side door handles Adapter sleeve

Combi door knob / handle Single-sided door handle

Some maintenance tips;

It is now mainly about mounting outside, in wind and weather, color changes due to weather influences may eventually occur here, you can prevent this by carrying out regular maintenance on your door fittings.

Antique iron door fittings;

For example, when you purchase uncoated iron door fittings and use them outside, you must first provide this fitting with a wax, otherwise you will have deposits on this fitting within a few days (especially in humid weather), it can even rust easily in the long run. By waxing you can easily prevent this. A wax can be purchased at any hardware store. We recommend that you perform this treatment once a year.

The iron fittings that are protected with a lacquer or epoxy layer and if damaged can easily rust, especially when used outdoors, for repairing damage you need a suitable coating. The hardware is often used in restorations and then painted along with the building element on which it is mounted.

Rusted fittings;

This fitting requires no maintenance because it is precisely the rust color that is desired. When used indoors, it can be rubbed with a dry cloth. When used outside, the hardware will slowly rust further. Rubbing with Vaseline slows down this process.

Brass fittings;

Brass is an alloy of copper and zinc. Untreated, this becomes increasingly dull due to oxidation, especially outside, but this process will take place much more slowly than with antique iron, for example. This is often a desirable result in older buildings and in restorations. If you want to keep unpainted brass shiny, it should be polished with a good copper polish, polishing first if necessary. For protection, a layer of clear wax can be applied after brushing.

Brass fittings lacquered;

This fitting is factory-coated with a transparent coating that protects the product against oxidation. The quality of the paint determines the duration of protection. Over time, the paint wears off, especially outside, leaving stains and pips. The product cannot then be polished because the lacquer layer must first be removed. The product can then be treated as unpainted brass and repainted if necessary.

Stainless steel fittings;

Despite the name stainless steel or stainless steel, stainless steel appears to be able to oxidize in practice and it also needs maintenance. There are different grades of stainless steel that are more or less stainless. Regular cleaning with water and green soap and then putting it in Vaseline helps. You can also use the stainless steel cleaner and, in case of more serious deposits, use stainless steel cleaner in combination with fine steel wool.

Finally, maintenance of the locks;

Locks:

Provide the day and night bolts with a little grease once every two years. Do not paint the front plate with the door, as this will disrupt the function of the bolts.

Cylinders:

Spray once every two years with a special lock spray, absolutely do not use oil or other products for lubrication.

Drangers:

Provided with grease on the pivot points.

Hinges:

Lubricate once a year with silicone spray, grease or oil.

Window fittings:

Regularly lubricate the pivot points with oil or teflon spray.

Kind regards;

Team Decohomeandgarden.com